| Chemical Composition Limits | |||||||||||||

| Weight% | Al | Si | Fe | Cu | Mn | Cr | Mg | Ni | Zn | Ti+Zr | Ti | Other Each | Other Total |

| 2014 | Rem | 0.50-1.20 | 0.7 max | 3.9 - 5.0 | 0.4 - 1.2 | 0.10 max | 0.2-0.8 | - | 0.25 max | - | 0.15 max | 0.05 max | 0.15 max |

5754 Aluminium Sheets Suppliers , 5456 Aluminium , 5086 Aluminium Sheet Prices, 5083 Aluminium Suppliers, 5086 Aluminum Sheet Suppliers

Whether you need an offshore specification 5754 Aluminium Sheets in Singapore, High Tensile Plate in Indonesia, or a pressure vessel plate in Saudi Arabia, we have floating stock of 800 ton Steel plates and logistical skills to deliver what you want when you need it.

At our stockyard / warehouse in Kalamboli, Navi Mumbai, Maharashtra, INDIA Steel Plates are available in a wide range of special metal grades like Manganese Steel, Alloy Steel, and Stainless Steel in numerous specifications. All Steel Plates Stocks are held to ASME, ASTM, EN, and API, Steel Plates are always available in surplus stock up to 15 metres long, 4 metres wide, and 300 millimetres thick. We are able to offer a solution to virtually any sourcing problem about Steel Plates.

R-Pipe Overseas is the only supplier of High Tensile Plate, Plate, Abrex 400 Steel Plate, Wear Resistant Steel, Sailhard Tiscral Las 07 Plate, Ar 400 Plate, High Manganese Plate, Hardfield Manganese Plate, Welten 780E Plate in India who delivered steel plates to Saudi Arabia in 3 days, to Sri Lanka in 2 days, to Iran in 8 days, to Singapore in 12 days, to Kuwait in 5 days, to United Arab Emirates in 3 days, to Japan in 10 days, to Qatar in 4 days, to Indonesia in 7 days & to Taiwan in 5 days. In Short R Pipe overseas has proven record that We are the only one who can supply Steel Plates to Gulf & Asian countries in minimum lead time, So If you want to buy 5086 / 5083 Aluminium Sheet Plate from reliable supplier & Steel Plates specialiest in INDIA, check our free quote with minimum delievery time to your country which you will receive within an hour.

5754 Aluminium Sheets

Aluminium Alloy 2014 Plate

Aluminium Alloy 2014 (2014 A) is a copper based alloy with very high strength together with excellent machining characteristics. Alloy 2014 is commonly used in many aerospace structural applications due to its high strength. Other applications include military vehicles, bridges, weapons manufacture and structural applications. We are Stockists of Aluminium plate 2014 in various customized specifications in terms of sizes and other related grades. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

Aluminium Alloy 2014 (2014 A) is a copper based alloy with very high strength together with excellent machining characteristics. Alloy 2014 is commonly used in many aerospace structural applications due to its high strength. Other applications include military vehicles, bridges, weapons manufacture and structural applications. We are Stockists of Aluminium plate 2014 in various customized specifications in terms of sizes and other related grades. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

Supplied Forms:

- • Round Bar is stocked in the range 1/2inch to 10inch diameter.

- • Plate is stocked in thicknesses 1/2inch to 4 inch.

- • Bar

- • Plate

- • Corrosion Resistance

- • Resistance to atmospheric attack:

- • Poor, especially when exposed to water or salt

- • Environments.

- • To protect against atmospheric corrosion in storage, lightly coat with Lanolin based protective Oil.

Weldability:

- • Brazing & Soldering - Not recommended

- • Oxygen - Not recommended

- • Inert Gas - Not recommended

- • Resistance, Spot, Beam - Excellent

- • Surface Treatment

Anodizing:

- • Protective - Fair

- • Bright - Unsuitable

- • Hard - Good

- • Colour - Fair (Dark colour only)

- • Plating

- • Very Good

Technical Data Sheet:

- A high strength 4 to 5% Copper alloy produced in extruded bar and profile form, in the fully heat-treated condition (solution heat-treated & artificially aged).Normally stocked in the T651 condition (stress relieved by controlled stretching) Except for sizes under 10mm diameter and over 203.2mm diameter. (T6 only). Over 203.mm diameter is manufactured to chemical composition only.

- Machinability of aluminium alloy 2014A is very good.

- Typical applications of aluminium alloy 2014A are high strength components especially for use in the aerospace and defence industries.

Aluminum Alloy 7075 Plate

Aluminum alloys have strong corrosion resistance. At subzero temperatures, their strength increases, thus making them a useful low-temperature alloy. Their strength decreases if they are subjected to very high temperatures. The aluminum 7075 alloy has high strength. Owing to our sound infrastructure facilities, we are successfully catering to the requirements of our clients by bringing forth a uniquely designed array of Aluminum Alloy 7075. Designed and developed at our state-of-the-art manufacturing unit, these products are highly utilized for various applications. With the aid sophisticated machinery and cutting-edge technology, our products are manufactured utilizing quality-approved raw material. The following datasheet gives more details about the aluminum 7075 alloy.

Aluminum alloys have strong corrosion resistance. At subzero temperatures, their strength increases, thus making them a useful low-temperature alloy. Their strength decreases if they are subjected to very high temperatures. The aluminum 7075 alloy has high strength. Owing to our sound infrastructure facilities, we are successfully catering to the requirements of our clients by bringing forth a uniquely designed array of Aluminum Alloy 7075. Designed and developed at our state-of-the-art manufacturing unit, these products are highly utilized for various applications. With the aid sophisticated machinery and cutting-edge technology, our products are manufactured utilizing quality-approved raw material. The following datasheet gives more details about the aluminum 7075 alloy.Chemical Composition:

The following table shows the chemical composition of the aluminum 7075 alloy.

Element | Content (%) |

Aluminum, Al | 90 |

Zinc, Zn | 5.6 |

Magnesium, Mg | 2.5 |

Copper, Cu | 1.6 |

Chromium, Cr | 0.23 |

Physical Properties:

The physical properties of aluminum 7075 alloy are tabulated below.

Properties | Metric | Imperial |

Density | 2.8 g/cm3 | 0.101 lb/in3 |

Melting point | 483°C | 900°F |

Applications include:

- • Aircraft fittings

- • Gears and shafts

- • Fuse parts

- • Meter shafts and gears

- • Missile parts

- • Regulating valve parts

- • Worm gears

- • Keys

- • Commercial aircraft

- • Aerospace

- • Defense equipment

Machinability and Weldability:

- • 7075 in the T6 condition has a machinability rating of 80% when compared to 2011 at 100%. Aluminum 7075 is can be formed in the annealed condition. and can be forged in the temperature range of 700 Degrees to 900 Degrees F. It should be solution heat treated following forging. Aluminum 7075 is a very poor choice for welding. Resistance welding is the only preferred method of joining 7075. Gas welding should be avoided and the use of arc welding may result in degradation of corrosion resistance.

Corrosion:

- • Moderate corrosion resistance

- The over aged -T73 and -T7351 tempers

- Offers good stress-corrosion cracking resistance as compared to the -T6 and -T651 tempers

Heat Treating:

- • 7075 may be solution annealed at 900 Degrees F for 2 hours at temperature, followed by a water quench. The alloy may then be given a precipitation hardening (aging) heat treatment.

Anodizing:

- • Good using commercially available methods

- • The alloy can be both hard and clear-coat anodized

Annealing:

- • Annealing is done at 775 Degrees F, holding for 3 hours at temperature. Controlled cooling at 50F per hour should then be used down to 500F from which it can be air cooled.

- • Aluminium Alloy 7075 offers the highest strength of the common screw machine alloys. The superior stress corrosion resistance of the T173 and T7351 tempers makes alloy 7075 a logical replacement for 2024, 2014 and 2017 in many of the most critical applications. The T6 and T651 tempers have fair machinability. Alloy 7075 is heavily utilized by the aircraft and ordnance industries because of its superior strength.

Aluminium Plate 6082

We are Stockists of Aluminium plate 6082 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium plate 6082 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

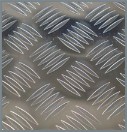

Aluminium Chequered Plates

With the aid of modern tools and sophisticated technologies, we have been able to provide the customers with an astounding Aluminum Chequered Sheets. Our customers' can avail this range from us in various dimensions, thickness and sizes as per their requirements. Widely appreciated for their features like longer service life, dimensional accuracy and robust construction. The following specifications cover Aluminum in demand.

The range finds extensive usage in:

- • Transport vehicles

- • Industrial sheds

- • Fabrication industry

Technical Details:

| Type | Aluminum checkered plate |

| Alloy Type | 3003 |

| Temper | O,H14,H16,H18,H22,H24,H26,H28,H32,H34,H36,H38,H112,F,H111 |

| Shape | 5 bar |

| Ridge height | 0.8-1.2mm |

| Ridge Length | 38mm |

| Thickness | 1.0 -6.0 mm |

| Width | 500mm-2300mm |

| Length | 500-10000mm |

| Adopted Standard | GB/T 3880-2006 ,EN485,ASTM B209 |

The representative series of this series aluminum tread plate is 6061 series. The main ingredient of this series aluminum tread plate includes magnesium and silicium elements. As a result, it has the features of both 4000 and 5000 series.

- • Pattern: finger, 2bars, 3bars, 5bars, and diamond bars

Features of 6061 Series Aluminum Tread Plate

- • It is a kind of aluminum tread plate which can be forged with cold treatment and can be used in situations which have high demand in anti-corrosion and oxidation.

- • As a result of its good availability and its connector with super features, it is easily coated and has good processability.

Applications of 6061 Series Aluminum Tread Plate

This series aluminum tread plate can be used in processing airplane parts, camera parts, couplers, ship parts, hardware, electronic accessories and joints, valves and valve parts, etc. It can also be used in low tension weapons and connectors in airplane.

You can use aluminum checkered sheets in the floor of automobile, airplane, light rail, vehicle steps, stair treads, elevators, etc. You also can use checkered sheets in your garage or workshop for a variety of purposes.

In order to better serve our customers, we also provide aluminium slit coil, aluminum sheet, aluminum coil, embossed aluminum sheet, aluminum strip, anodising aluminum sheet, coated aluminum coil, etc. If you would like more information about our products, we welcome you to contact us at any time!

Dimensions can be produced according to your specifications,Very good elongation, anti-corrosion,Generally used in industry and architecture industries

This alloy aluminum in the main alloy elements as magnesium and silicon, with middle strength, good corrosion resistance, weldability, oxidation effect is good. Widely applied to the requirements of a certain strength and resistance high range of industrial structure, such as the manufacture of the truck, the tower building, ship, train, railway vehicles, furniture, etc.

Aluminum Sheet 5052 H32

Leveraging to our wide distribution network, we are able to offer our clients a dimensionally accurate range of Aluminum Alloy 5052 H32. Having excellent finishing properties, our offered 5052 is referred as anodize quality aluminum. Good resistance to corrosion, especially in salt-water/marine atmospheres, these alloys offered by us are highly applauded in the market.

Leveraging to our wide distribution network, we are able to offer our clients a dimensionally accurate range of Aluminum Alloy 5052 H32. Having excellent finishing properties, our offered 5052 is referred as anodize quality aluminum. Good resistance to corrosion, especially in salt-water/marine atmospheres, these alloys offered by us are highly applauded in the market.Other details:

- • Anodized coatings are bright and clear

- • The major alloying element in 5052 is magnesium in sufficient quantities

- • Cause substantial lowering of the melting point

- • Do not produce brittleness

- • 5052 is far stronger than the 1100 or 3000 series aluminiums

- • Forms with reasonable bend radii

- • WelMin 90 degree cold bend radius (for .064" thick): 1T The above values are average and may be considered as representative of 5052-H32 applications.

5052 is widely used for cooking utensils, food processing equipment, storage tanks, truck and trailer components, mail boxes, aircraft components, electronic chassis, boat hulls, deck houses, hatch covers, pressure vessels, ladders, railings, frames, drip pans, tool boxes, truck bumpers, inner and outer body panels and components in truck and auto industries, kitchen equipment, decorative trim, architectural uses, signage applications, and any number of parts and application requiring strength and good formability at reasonable cost.

Machinability and Weldability:

- • 5052-H32 has a machinability rating of 88% when compared to 2011 at 100%.

- • 5052-H32 can be readily welded using all the common welding techniques. 5052 has the best welding characteristics of all the aluminiums.

Heat Treating:

- • 5052 is not heat treatable, durability is very good

5052-H32 Conforms to:

- • ASTM BB209

- • QQ-A-250/8

- • AMS 4015

- • AMS 4016

- • AMS 4017

Applications:

- • For cooking utensils

- • Food processing equipment

- • Storage tanks

- • Truck and trailer components

- • Mail boxes

- • Aircraft components

- • Electronic chassis

- • Boat hulls

- • Deck houses

- • Hatch covers

- • Pressure vessels

- • Ladders

- • Railings

- • Frames

- • Drip pans

- • Tool boxes

- • Truck bumpers

- • Inner and outer body panels and components in truck

- • Auto industries

- • Kitchen equipment

- • Decorative trim

- • Architectural uses

- • Signage applications

Applications:

- • 5052 is widely used for cooking utensils, food processing equipment, storage tanks, truck and trailer components, mail boxes, aircraft components, electronic chassis, boat hulls, deck houses, hatch covers, pressure vessels, ladders, railings, frames, drip pans, tool boxes, truck bumpers, inner and outer body panels and components in truck and auto industries, kitchen equipment, decorative trim, architectural uses, signage applications, and any number of parts and application requiring strength and good formability at reasonable cost.

Aluminum Alloy 5083 plate

Keeping in mind the latest market dynamics, we are engaged in offering our clients a high in strength Aluminum Alloy 5083. Due to the excellent ductility feature, these alloys offered by us retain good formability, highly resistance to corrosion and are applicable in marine applications. Having low density and excellent thermal conductivity, the aluminum alloys offered by us are in accordance with the industry set guidelines.

Keeping in mind the latest market dynamics, we are engaged in offering our clients a high in strength Aluminum Alloy 5083. Due to the excellent ductility feature, these alloys offered by us retain good formability, highly resistance to corrosion and are applicable in marine applications. Having low density and excellent thermal conductivity, the aluminum alloys offered by us are in accordance with the industry set guidelines.Aluminum Alloy 5083 contains:

- • 5.2% magnesium

- • 0.1% manganese

- • 0.1% chromium

Typical Applications:

- • Require a weldable alloy of high to moderate strength

- • Good corrosion resistance

- • Used in Marine applications

- • Unfired welded pressure vessels

- • TV towers

- • Drilling rigs

- • Transportation equipment

- • Armor plate

Principal design features:

- • This is a non-heat treatable alloy for strengthening

- • Very good corrosion resistance

- • Easily welded

- • Does have good strength

Applications:

- • Commonly used in the manufacture of unfired

- • Welded pressure vessels

- • Marine

- • Auto aircraft cryogenics Aluminium Alloy 5086

- • Drilling rigs

- • TV towers

- • Transportation equipment

- • Missile components

Other physical properties:

- • Electrical conductivity 28% of copper

Other mechanical properties:

- • Shear strength in O temper is 25 KSI 3.8

Forms & shapes:

- • Wire

- • Sheet

- • Plate

- • Strip

- • Round bars

- • Hexagonal

- • Flats

- • Square

- • Angle

- • Channel

- • Blanks

- • Tubes

- • Pipes

- • Special shape forgings

Aluminium Sheets Alloy 5052

With the help of our expert team and skilled engineers able to offers our client dimensionally accurate Aluminum Sheets Alloy 5052. Having excellent finishing properties, our offered product is referred as anodize quality aluminum. Good resistance to corrosion, especially in salt water/Marine atmospheres. These alloys offered by us are highly applauded in market. Aluminum Sheet Alloy 5052 is mainly used for Cooking utensils, Food processing equipments, Storage tanks, and many more. Also used in inner and outer panels and components in trucks.

With the help of our expert team and skilled engineers able to offers our client dimensionally accurate Aluminum Sheets Alloy 5052. Having excellent finishing properties, our offered product is referred as anodize quality aluminum. Good resistance to corrosion, especially in salt water/Marine atmospheres. These alloys offered by us are highly applauded in market. Aluminum Sheet Alloy 5052 is mainly used for Cooking utensils, Food processing equipments, Storage tanks, and many more. Also used in inner and outer panels and components in trucks.Features:

- • Bright and clear coating

- • Do not produce brittleness

- • Cause substantial lowering of the melting point

Aluminium Patterned Sheets

Our Aluminium Patterned Sheet are ideal for decorative applications and interior panelling for trucks, cabins, etc. Available in five designs — diamond, five-bar, two-bar, propeller, north star — the sheets can be bent easily or curved to take the shape of the structure in which they are fixed. Pattern sheets are light, rust-free, hygienic and easy-to-clean and because they are made from aluminium, they are resistant to corrosion and denting. The sheets are manufactured with state-of-the-art equipment employing sophisticated process technology. With stringent quality control measures in place, the company sets the standard in aluminum paneling.

Our Aluminium Patterned Sheet are ideal for decorative applications and interior panelling for trucks, cabins, etc. Available in five designs — diamond, five-bar, two-bar, propeller, north star — the sheets can be bent easily or curved to take the shape of the structure in which they are fixed. Pattern sheets are light, rust-free, hygienic and easy-to-clean and because they are made from aluminium, they are resistant to corrosion and denting. The sheets are manufactured with state-of-the-art equipment employing sophisticated process technology. With stringent quality control measures in place, the company sets the standard in aluminum paneling.Specifications:

| Alloy (AA) | Temper | UTS (mpa) | Bend test:Â radius of bend T=material thickness | |

| Min | Max | |||

| 1200 | H14 | 105 | 140 | 1/2T |

| 1200* | M | - | - | - |

| 3003 | H14 | 130 | 180 | 1/2T |

| 3003 | M | - | - | - |

| 3105 | H14 | 150 | 200 | 1/2T |

| 3105* | M | - | - | - |

| 8011 | H14 | 125 | 160 | 1/2T |

| 8011* | M | Â - | - | - |

Aluminium Plate

Aluminum Plate can be used in various applications due to unbeatable strength to weight ratio compared to other metals.Weighing in at 1/3 as much as Iron, steel, copper or brass, aluminum is the most abundant metal element in Earth's crust and makes up about 8% by weight.

Aluminum is corrosion resistant and and virtually maintenance free. It has good heat conductivity, better than any other common metal and conducts electricity comparable to copper products. Aluminum is also non-toxic and can be used in food preparation equipment. Aluminum plates reflective nature is suitable for light fixtures, is non-combustible and so does not burn.

We stocks several grades of aluminum plate including the following: 1100, 2024, 3003, 5052, 5083, 6061, 6082, 7075, 8011. 1100-0 is used primarily for spinning and deep drawing operations such as utensils, ornaments, etc.

1100-H14 and 3003-H14 are specification alloys used for general forming operations.

2024 is the most widely used aerospace alloy. With the combination of high yield strength and good fatigue resistance. Also has good machinability and grain structure. Great for precision fittings and parts.

3003 reacts well to finishing such as laminating or anodizing. 5052 is a similar alloy with better corrosion resistance and strength. Excellent weldability, formability, with good corrosion resistance make 3003 Aluminum Plate a popular and economical choice. 3003 Aluminum Plate has a smooth, shiny finish and is popular for many cosmetic and industrial applications, including: decorative trim, fuel tanks, food & chemical handling etc.

5052-H32 and H34 is a superior strength alloy of good forming qualities and is especially suited for Marine applications. Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Plate a common choice for chemical, marine or saltwater applications. 5052 Aluminum Plate applications include: tanks, drums, marine hardware, boat hulls, etc.

5083 is one alloy of different tempers that produces high weld joint efficiencies. It is used for tank work, heavy transport, etc., where its welded properties can be used to advantage.

6061 alloy aluminum plate is the most versatile and widely used of heat treat grades. Excellent machinability, weldability and medium strength. Has great welding and brazing abilities due to its high corrosion resistance at all temperatures. It is used for all structural applications such as mine cars, logging chutes, and ship construction. 6061 Aluminum Plate is ideal for structural framing, base plates, motorcycle & automotive parts, etc. Aluminium alloy 6082 is a medium strength alloy with excellent corrosion resistance. It has the highest strength of the 6000 series alloys.

Alloy 6082 is known as a structural alloy. In plate form, 6082 is the alloy most commonly used for machining. As a relatively new alloy, the higher strength of 6082 has seen it replace 6061 in many applications. The addition of a large amount of manganese controls the grain structure which in turn results in a stronger alloy. It is difficult to produce thin walled, complicated extrusion shapes in alloy 6082. The extruded surface finish is not as smooth as other similar strength alloys in the 6000 series. 6082 is typically used in Highly stressed applications, Trusses, Bridges, Cranes, Transport applications, Beer_ barrels, Milk churns.

7075 is the highest strength aluminum plate. Can be used in air-frame structures and aircraft parts. Some end uses for all grades of aluminum include transportation, food packaging, furniture, electrical applications, building, construction, machinery and equipment.

Aluminum Plates

The company manufactures Aluminum Plates in standard sizes by using aluminum scrap and aluminum Ingots. Sheets produced have aluminum content of about 99.50% purity. The company manufactures aluminum slabs, sheets and plates of various sizes with thickness ranging between 2 mm to 120 mm. We are into offering the clients with Rolled Aluminium Plates that are available in various dimensions and grades to meet the client's specifications. Procured from reliable vendors, our range of Rolled Aluminium Plates is widely demanded in various industries. We are reckoned as one of the prominent Suppliers of Rolled Aluminium Plates from India.

Hot Rolled Plates:

| Alloy | 1xxx, 2xxx, 3xxx, 5xxx, 6xxx, 7xxx, 8xxx |

| Width Range | 800-1540 mm |

| Standard (Trimmed) | 915, 1220, 1400 and 1500 mm |

| Standard (Untrimmed) | 1270, 1540 mm |

| Thickness | 6-200 mm for 1xxx 10-200 mm for 3xxx, 4xxx 25-200 mm for 5xxx 8-20 mm for 2xxx, 6xxx (stretched) |

| Weight | Depends on dimensions |

| Temper | F / M, O, H1, H111, H112, T4, T6 |

| Finish | Mill Finish |

Cold Rolled Sheets:

| Alloy | 1xxx, 2xxx, 3xxx, 5xxx, 6xxx, 7xxx, 8xxx |

| Width Range | 800-1500 mm |

| Standard | 915, 1000, 1159, 1220, 1300, 1321, 1500 mm |

| Length Range | 1830-4350 mm |

| Standard | 2440, 2540, 2745, 3000, 3050 mm |

| Thickness | 0.56-4.00 mm (length & width for sheets having thickness of over 4.00 mm is subject to confirmation) |

| Weight | Depends on dimensions |

| Temper | O, H1, H2, H3, H4, T4, T6 |

| Finish | Mill Finish |

Our Range as follow:

- • Aluminium Plates (Rolled)

- • Thickness 6-150mm

- • Width 1000-2100mm

- • Length 2000-6000mm

- • Alloys 5083 (in H111/H112/O tempers)

- • 6061/6082, 7075/7050, 2024/2014/2017 / Tempers: T651 or T451 temper (Stretched and stress relieve)

- • Aluminium Thick plates (by forging, cold compression and all sizes milled T652 temper)

- • 151-350mm thickness

- • Width 800-1500mm

- • Length 1000-2800mm

- • Alloys 5083, 6061/6082 (T652 temper), 7075/7050 as well.

Specifications

- • Grade : 6351T6, 6061T6, 40800, 19000

- • Sizes (In mm) : 6.35, 7.5, 8, 10, 12.7, 13, 15.8, 19, 20, 25, 32, 38, 40, 50, 63, 76, 80, 100, 127

Salient Features

- • Durable

- • Rust proof

- • High tensile strength

- • Longer working life

Aluminum Plates is resistance to corrosion and abrasion. This range finds extensive applications in aircraft fittings, camera lens mounts, coupling, marine and electrical fittings. Being inert to chemicals, this range is of great utility for food and chemical handling, fuel tanks, pressure vessels and in a variety of structural areas.

Aluminium Sheet 3003

Principal Design Features:

Principal Design Features:- • AL 3003 is an alloy with very good corrosion resistance and moderate strength. It is not heat treatable and develops strengthening from cold working only.

Tempering:

- • Not applicable.

Applications:

- • Commonly used in chemical equipment, ductwork, and in general sheet metal work. 3003 is also used in the manufacture of cooking utensils, pressure vessels, builder's hardware, eyelet stock, ice cube trays, garage doors, awning slats, refrigerator panels, gas lines, gasoline tanks, heat exchangers, drawn and spun parts, and storage tanks.

Aging:

- • Not applicable to this alloy.

Machinability:

- • The AL 3003 alloy is readily machined and is considered as having good machinability for the aluminum alloys,.

Forming:

- • This alloy is readily formed by either conventional cold working or hot working.

Welding:

- • Welding is readily accomplished by means of conventional welding methods. Filler rod is generally AL 1100 alloy. When welding AL 3003 to other aluminum alloys, such as 5052, 6061 or 6062 the filler rod should be AL 4043.

Heat Treatment:

- • AL 3003 is a non-heat treatable alloy.

Forging:

- • The alloy may be hot forged in the range of 950 F to 500 F.

Hot Working:

- • The hot working range (as for forging) is 950 F to 500 F. In that range the alloy is easily hot worked.

Cold Working:

- • AL 3003 alloy is readily cold worked by all conventional methods..

Annealing:

- • Annealing, during or following cold working, is done at 775 F, allowing adequate time for thorough heating, followed by air cooling.

Other Physical Props:

- • Electrical conductivity 40% of copper.

Hardening:

- • Hardens as a result of cold working only.

Other Mechanical Props:

- • Shear strength for O temper (annealed) is 11 ksi. For H14 (cold worked) it is 14 ksi.

Services:

- • All stock items can be shipped out within 24 hours, usually within the same day. Even cutting orders for bar or sheet can be processed and dispatched the same day.

Aluminium Plate 5083

We are Stockists of Aluminium Plate 5083 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Plate 5083 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

Aluminium Plate 19000

We have founded ourselves as a recognized suppliers of Aluminium Plate 19000.

Aluminium Plate 6061

We are Stockists of Aluminium Plate 6061 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Plate 6061 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

Aluminium Sheet 1100

Aluminum 1100

Aluminum 1100 is soft, low strength and, at 99% aluminum composition, is the commercially pure grade among aluminum alloys.

Aluminum 1100 is a soft material and is used to make many common household items, such as cooking utensils, household foil, and food containers. Aluminum 1100 is also used in a wide range of industrial applications, involving both thermal and electrical conductivity. Artists appreciate the ability to form shapes using stamps, engravers and other light-weight tools.

Aluminum 1100 is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications where eye appeal is important.

Principal Design Features |

| This alloy is commercially pure aluminum with excellent forming characteristics. |

Applications |

| Commonly used in spun hollowware, fin stock, heat exchanger fins, dials and name plates, cooking utensils, decorative parts, giftware, rivets and reflectors, and in sheet metal work. |

Welding |

| Readily welded by all conventional methods. Use AL 1100 consumable electrodes and filler wire. |

Forming |

| Forming, either hot or cold, is readily accomplished with this alloy. In the annealed condition the alloy can be cold worked extensively without an intermediate anneal. |

Machinability |

| This alloy has very good machinability. Best results are obtained when machining is done with the alloy in hard temper. Carbide tooling is preferred, but high speed steel tooling may also be used. For heavy cuts an oil lubricant should be used otherwise turning may be done dry. |

Aluminum Checkered Plate

We are offering high strength Aluminum Checkered Plate to our clients is different sizes as required by them. These Aluminum Checkered Plates are manufactured from high grade quality raw materials.

We are offering high strength Aluminum Checkered Plate to our clients is different sizes as required by them. These Aluminum Checkered Plates are manufactured from high grade quality raw materials.Aluminum Checker Plate costs less but gives more

Aluminum checker plate is widely used in decorative, shipbuilding and architectural applications. Having good forming, drilling and welding ability, Aluminum Diamond Plate is easy to fabricate and its raised diamond lug pattern provides good slip resistance.

Standard dimensions:

Thickness 2.0 - 10.0mm, width and length can be customized cut to suit size.3003-H22 – Bright Finish Bendable5086-H112 – Excellent Corrosion Characteristics6061-T6 – Structural Applications – Not Bendable

Excellent for locations requiring metal, skid resistant floors. The non-sparking characteristic adds a measure of safety where combustibles are present.

How is it Measured? Thickness not including diamond (A) X Width X Length

Aluminum diamond plate, sometimes called aluminum tread plate, aluminum floor plate, or aluminum checker plate, is available in 6061-T6 and 3003-H14 sizes. The 6061-T6 alloy has a dull mill finish and is harder and more durable, and the 3003-H14 has shiny bright finish, and is softer and more formable. Aluminum tread plate is commonly seen on fire trucks and truck toolboxes.

Aluminum checker plate specific applications

- • Vehicle

Characteristics and benefits: light weight transport sector is required, the best comer of an aluminum alloy step. Increase the energy-saving effect.

Applications: checker plate floor, such as van-type vehicle catwalk flooring, wood step of the bus or truck, train inspection hole lid, tank car, the car cold storage. - • Ship

Characteristics and benefits: because the excellent corrosion resistance in seawater, requires no resistance such as repainting. It can be used with confidence for many years.

Applications: corridor and bridges over the lid and floors, stairs, cabin deck, fish tank, gangway to the floating dock. - • Architecture

Characteristics and benefits: corrosion resistance of the step corner has been utilized shopping and tourist attractions that require aesthetics, such as collective for many years.

Applications: floors, stairs, shelves, such as gutter lid, the bicycle. - • Plant

Characteristics and benefits: harmless because it is also suitable for container species, such as facilities and chemical plants and food plant is excellent in chemical resistance.

Applications: bench floor and stairs, equipment/ plant machinery, such as ambulatory inspection. - • Other

Characteristics and benefits: because it has many excellent characteristics. Not only as a materials step, has also been used in the case and ornaments.

Applications: such as a deck ladder, ladder, showcase, temporary scaffolding, the structure of marine.

Aluminium Plate 5086

We are Stockists of Aluminium Plate 5086 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Plate 5086 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

Aluminium Plate 7075

We are Stockists of Aluminium Plate 7075 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Plate 7075 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

Aluminium Rolled Plates

We offer Aluminium Rolled Plates used in various industrial & commercial applications. Our Aluminium Rolled Plates are suitable for further applications. We make Aluminium Rolled Plates as per the requirements of our clients also.

We offer Aluminium Rolled Plates used in various industrial & commercial applications. Our Aluminium Rolled Plates are suitable for further applications. We make Aluminium Rolled Plates as per the requirements of our clients also. Features:

- • Durability

- • Rust resistance

- • High tensile strength

Specification:

| Width | 870 mm – 1350 mm |

| Standard Width | 870 mm, 915 mm, 1220 mm |

| Length | 610 mm – 4880 mm |

| Standard Length | 2440 mm |

| Thickness | 6.0 mm – 150 mm |

| Alloy | 19000, 40800 |

Aluminium Plate 6063

These Aluminum Sheet & Plates are broadly valued by our clientele for its smooth finish & provided in several stipulations. This Aluminum Sheet Plates 6063 is featured with qualities like durability, Optimum accuracy and utility with good resistance with corrosion. The use of our products presents great potential for increasing the sustainable use of energy. Aluminum’s light weight contributes to increased fuel efficiency in vehicles ranging from passenger cars to armored tanks

These Aluminum Sheet & Plates are broadly valued by our clientele for its smooth finish & provided in several stipulations. This Aluminum Sheet Plates 6063 is featured with qualities like durability, Optimum accuracy and utility with good resistance with corrosion. The use of our products presents great potential for increasing the sustainable use of energy. Aluminum’s light weight contributes to increased fuel efficiency in vehicles ranging from passenger cars to armored tanks Features:

- • Corrosion & heat resistance

- • Easy installation

- • Long lasting life

Aluminum Alloy 2024

Owing to our sprawling infrastructure, we are able to fulfill the requirements of our client' by offering Aluminum Alloy 2024. It is a cold finished aluminum wrought product that has good machinability, surface finish capabilities and deep drilling characteristics. Further, these products are ideal for applications requiring high strength and are manufactured in compliance with the international standards of quality.

Owing to our sprawling infrastructure, we are able to fulfill the requirements of our client' by offering Aluminum Alloy 2024. It is a cold finished aluminum wrought product that has good machinability, surface finish capabilities and deep drilling characteristics. Further, these products are ideal for applications requiring high strength and are manufactured in compliance with the international standards of quality.Other details:

- • High strength aluminum screw machine stock alloy

- • Typical tensile strengths in the T351 and T4 temper equal

Typical applications include:

- • Fasteners Etc.

- • Aircraft fittings and structures

- • Computer parts

- • Gears

- • Shafts

- • Hinge pins

- • Valve blocks and valve parts

- • Bolts

- • Nuts

- • Fasteners

- • Truck parts

- • Brake components

Machining of Aluminum Alloy 2024:

- • Alloy 2024 offers good machinability when machined using single-point

- • Multi-spindle carbide tools on Screw machines

- • The use of a chip breaker is recommended

Anodizing:

- • Anodizing response is rated moderate for the alloy

- • Alloy 2024 can accept all types of anodic coatings

Principal design features:

- • Precipitation hardening alloy with good strength after heat treatment

Applications:

- • To manufacture of aircraft structures and truck frames

Other Physical Properties:

- • Electrical conductivity 33% of copper

Other Mechanical Properties:

- • Shear strength: O (annealed) temper 18 KSI

- • T4 temper 38 KSI

- • T6 Temper 42 KSI

Forms & shapes:

- • Wire

- • Sheet

- • Plate

- • Strip

- • Round bars

- • Hexagonal

- • Flats

- • Square

- • Angle

- • Channel

- • Blanks

- • Tubes

- • Billets

- • Pipes

- • Pipe fittings

- • Forging rings

- • Special shape forgings

- • Fasteners

Aluminium Sheet 5086

We are Stockists of Aluminium Sheet 5086 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Sheet 5086 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

Aluminium Plate 5052

We are Stockists of Aluminium Plate 5052 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Plate 5052 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.Features:

- • High strength

- • Corrosion resistance

- • Machinability

Aluminium Sheet 6061

We are Stockists of Aluminium Sheet 6061 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

We are Stockists of Aluminium Sheet 6061 in various customized specifications in terms of sizes and other related grades. Superior quality aluminum and latest product process are used in the fabrication of these sheet plates. These plates find application in high stress applications, trusses, bridges, cranes, transport applications, ore skips, barrels and milk churns.

Aluminum Embossed Sheets

We are offering superior quality Aluminum Embossed Sheets in various decorative finishes for interiors and innovative designing. The material used is fluorocarbon, coated aluminum, coated aluminum sheet, aluminum roll, Light aluminum & brushed aluminum rolls, by embossing the surface of aluminum sheets elegant, streamlined good, solid sense. Embossed aluminum sheet can enhance the strength of aluminum sheet, stiffness, and does not affect the original surface layer of the aluminum sheet with the performance.

We are offering superior quality Aluminum Embossed Sheets in various decorative finishes for interiors and innovative designing. The material used is fluorocarbon, coated aluminum, coated aluminum sheet, aluminum roll, Light aluminum & brushed aluminum rolls, by embossing the surface of aluminum sheets elegant, streamlined good, solid sense. Embossed aluminum sheet can enhance the strength of aluminum sheet, stiffness, and does not affect the original surface layer of the aluminum sheet with the performance.Features:

- • Easy and fast fabrication

- • No creep or damage

- • No health hazards

Aluminum Sheets

Our organization is dedicatedly involved in manufacturing, supplying and exporting a comprehensive range of Aluminum Sheets. Available in various dimensions, specifications, shapes and sizes, our offered sheets are manufactured in compliance with the highest benchmarks of quality. Extensively used in various industries, these sheets are manufactured utilizing high-grade aluminum and other basic material.

Our organization is dedicatedly involved in manufacturing, supplying and exporting a comprehensive range of Aluminum Sheets. Available in various dimensions, specifications, shapes and sizes, our offered sheets are manufactured in compliance with the highest benchmarks of quality. Extensively used in various industries, these sheets are manufactured utilizing high-grade aluminum and other basic material.Attributes:

- • High durability

- • Resistance against corrosion

- • Excellent finish

- • High strength

Technical Specifications:

- • Alloy: 1100,1050,1060,1070,1200,1235,2024,3003,3105,5052,5083,5754,8011

- • Temper: O, H16, H18, H22, H24, H26, H0.

- • Thickness: 0.15 - 150mm.

- • Width: 20 - 2,000mm.

- • Length: 1,000 - 6,000mm.

- • Dimensions can be as per clients' specifications.

- • Good plasticity and conductivity.

- • Generally used in industrial and construction applications

Offering Aluminum Sheet:

- • 6061 Aluminum Sheet, Plate, Temper: 6061-0, 6061-T4, 6061-T6, 6061-T451, 6061-T651, Bare: QQ-A-250/11, AMS 4025, AMS 4026, AMS 402 6061 ALUMINUM ALLOY PLATE / SHEET Temper: 6061-0, 6061-T4, 6061-T6, 6061-T451, 6061-T651 Bare: QQ-A-250/11, AMS 4025, AMS 4026, AMS 4027, ASTM-B-209 6061-0 Bare Aluminum Sheet Per AMS 4025, QQ-A-250/11 6061-T6 Bare Aluminum Sheet Per QQ-250/11 6061-T6 Aluminum Tube 6061-T651 Aluminum Round Bar Per AMS 4177.

Aluminium Square Sheet

Aluminium Square Sheet & Plate Aluminum in its various forms is stocked in a range of strengths varying from that of Specification 1100-0 (which has a yield strength of around 5000 lbs. per square inch) to that of Specification 7075-T6 (yield strength of about 70,000 lbs. per square inch).Here are a few typical applications within the range of these specifications – Utility Sheet, is used for all general sheet metal work such as flashings, ductwork, lining walls, etc. 1100-0 is used primarily for spinning and deep drawing operations such as utensils, ornaments, etc. 1100-H14 and 3003-H14 are specification alloys used for general forming operations. 5005-H14 similar in physical characteristics to 3003-H14 with superior corrosion resistance and a homogenous smooth surface finish suitable for anodizing. This alloy is suitable for curtain walls, decorative trim, control panel boxes and signs, etc. 5052-H32 and H34 is a superior strength alloy of good forming qualities and is especially suited for Marine applications. 5083-H321 and H323 is one alloy of different tempers that produces high weld joint efficiencies. It is used for tank work, heavy transport, etc., where its welded properties can be used to advantage 5454-H32 is a sister alloy to 5083 with a lower rating to stress corrosion when functioning in the 150°F to 300°F range. Typical uses are truck dump bodies, tanker trucks, exhaust stacks, chemical handling tanks on vessels, etc. 6061-T6 is an excellent all purpose alloy, having high strength and good corrosion resistance. It is used for all structural applications such as mine cars, logging chutes, and ship construction.

Aluminium Square Sheet & Plate Aluminum in its various forms is stocked in a range of strengths varying from that of Specification 1100-0 (which has a yield strength of around 5000 lbs. per square inch) to that of Specification 7075-T6 (yield strength of about 70,000 lbs. per square inch).Here are a few typical applications within the range of these specifications – Utility Sheet, is used for all general sheet metal work such as flashings, ductwork, lining walls, etc. 1100-0 is used primarily for spinning and deep drawing operations such as utensils, ornaments, etc. 1100-H14 and 3003-H14 are specification alloys used for general forming operations. 5005-H14 similar in physical characteristics to 3003-H14 with superior corrosion resistance and a homogenous smooth surface finish suitable for anodizing. This alloy is suitable for curtain walls, decorative trim, control panel boxes and signs, etc. 5052-H32 and H34 is a superior strength alloy of good forming qualities and is especially suited for Marine applications. 5083-H321 and H323 is one alloy of different tempers that produces high weld joint efficiencies. It is used for tank work, heavy transport, etc., where its welded properties can be used to advantage 5454-H32 is a sister alloy to 5083 with a lower rating to stress corrosion when functioning in the 150°F to 300°F range. Typical uses are truck dump bodies, tanker trucks, exhaust stacks, chemical handling tanks on vessels, etc. 6061-T6 is an excellent all purpose alloy, having high strength and good corrosion resistance. It is used for all structural applications such as mine cars, logging chutes, and ship construction.

Aluminum Corrugated Sheets

Aluminum Corrugated Sheets is ideal for all roofing and cladding needs. It is easy to use, durable and economical to work with.

Aluminum Corrugated Sheets is ideal for all roofing and cladding needs. It is easy to use, durable and economical to work with. Using aluminium for roofing has many benefits. Among these are the following:

- • Aluminium roofing sheets are extremely light and have a high strength-to-weight ratio.

- • Aluminium is an increasingly popular choice for use in installations and buildings. It is corrosion-resistant in almost any kind of environment. Even in highly corrosive industrial environments, it is resistant to fumes and vapours of organic compounds and to chemicals like ammonia, carbon dioxide and acids such as hydrochloric acid, nitric acid and sulphuric acid. Such corrosion resistance gives the metal a long life and keeps it looking good throughout its life.

- • The shine and brightness of aluminium livens its surroundings, and, because it doesn't stain, discolor or rot, it keeps its brightness and shine for a long time. Aluminium corrugated sheets can take a variety of finishes, colors and textures, which protect them and further enhance their appearance.

- • An alumunium structure can be easily dismantled, transported and re-assembled in a new location.

- • Though the metal is a good conductor of heat, its high reflectivity for radiant heat and light (75 to 80 per cent when new, 60 per cent after several years) keeps the interiors of aluminium building from five to eight degrees celsius cooler in summer, while its low emission rate cuts heat loss in winter.

- • It is easy to maintain and wash.

Aluminum Alloy 2014 plate

Being a client-centric organization, we are engaged in manufacturing, supplying and exporting a comprehensive range of Aluminum Alloy 2014. Manufactured at our sophisticated infrastructure unit, the aluminum alloy offered by us is highly applauded for their features like low maintenance, dimensional accuracy and high tensile strength. Further, our appointed quality controllers closely inspect our range on different parameters to ensure flawlessness.

Being a client-centric organization, we are engaged in manufacturing, supplying and exporting a comprehensive range of Aluminum Alloy 2014. Manufactured at our sophisticated infrastructure unit, the aluminum alloy offered by us is highly applauded for their features like low maintenance, dimensional accuracy and high tensile strength. Further, our appointed quality controllers closely inspect our range on different parameters to ensure flawlessness.Principal design features:

- • Precipitation hardening alloy with good strength after heat treatment

Applications:

- • To manufacture of aircraft structures and truck frames

Other Physical Properties:

- • Electrical conductivity 33% of copper

Other Mechanical Properties:

- • Shear strength: O (annealed) temper 18 KSI

- • T4 temper 38 KSI

- • T6 Temper 42 KSI

Forms & shapes:

- • Wire

- • Sheet

- • Plate

- • Strip

- • Round bars

- • Hexagonal

- • Flats

- • Square

- • Angle

- • Channel

- • Blanks

- • Tubes

- • Billets

- • Pipes

- • Pipe fittings

- • Forging rings

- • Special shape forgings

- • Fasteners

Specifications :

ASTM B209 | ASTM BB241 | QQ A-367 | ASTM B247 |

ASTM B210 | DIN 3.1255 | SAE J454 | ASTM B241 |

ASTM B211 | MIL T-15089 | UNS A92014 | QQ A-225/4 |

ASTM B221 | QQ A-200/2 | QQ A-250/4 |

|

Chemistry Data:

Aluminum | Balance |

Chromium | 0.1 max |

Copper | 3.9 - 5 |

Iron | 0.7 max |

Magnesium | 0.2 - 0.8 |

Manganese | 0.4 - 1.2 |

Remainder Each | 0.05 max |

Remainder Total | 0.15 max |

Silicon | 0.5 - 1.2 |

Titanium | 0.15 max |

Titanium + Zinc | 0.2 max |

Zinc | 0.25 max |

Aluminum Alloy 6082 plate

Owing to our excellent working force, we bring forth for our clients an exclusively manufactured range of Aluminum Alloy 6082. Applicable in aircraft fittings, couplings, camera lens mounts, electrical fittings & connectors, decorative or misc, marines fittings & hardware, hinge pins, brake pistons, hydraulic pistons, magneto parts, appliance fittings and bike frames, our offered alloys are widely demanded by various industries. Further, the alloy 6082 offered by us is manufactured in tandem with industry set guidelines.

Subcategory:

- • 6000 Series Aluminum Alloy

- • Aluminum Alloy

- • Metal

- • Nonferrous Metal

Composition Notes:

- • Aluminum content reported is calculated as remainder

- • Composition information provided by the Aluminum Association

- • It is not for design

Material Notes:

- • Excellent joining characteristics

- • Good acceptance of applied coatings

- • Combines relatively high strength

- • Good workability

- • High resistance to corrosion

- • The T8 and T9 tempers offer better chipping characteristics

Specifications:

| Component | Wt % |

| Al | 95.8 – 98.6 |

| Cr | 0.04- 0.35 |

| Cu | 0.15 – 0.4 |

| Fe | Max 0.7 |

| Mg | 0.8-1.2 |

| Mn | Max 0.15 |

| Other, each | Max 0.05 |

| Other, total | Max 0.15 |

| Si | 0.4 -0.8 |

| Ti | Max 0.15 |

| Zn | Max 0.25 |

Material Notes:

- • Excellent joining characteristics, good acceptance of applied coatings. Combines relatively high strength, good workability, and high resistance to corrosion; widely available. The T8 and T9 tempers offer better chipping characteristics over the T6 temper

- • Data points with the AA note have been provided by the Aluminum Association, Inc. and are not for design

Electrical Properties:

| Electrical Resistivity | 3.99e-006 ohm-cm | 3.99e-006 ohm-cm | AA; Typical at 68°F |

Processing Properties:

| Solution Temperature | 529 °C | 985 °F | |

| Aging Temperature | 160 °C | 320 °F | Rolled or drawn products; hold at temperature for 18 hr |

| Aging Temperature | 177 °C | 350 °F | Extrusions or forgings; hold at temperature for 8 hr |

Aluminum Alloy 5086 Plate

Backed by rich industry experience, we are engaged in providing our clients with a quality-assured range of Aluminum Alloy 5086. Precision-engineered, our offered aluminum alloy is manufactured utilizing quality approved raw material and other basic components that are sourced from reliable vendors of the industry. Further, our offered products are manufactured in adherence with the international standards of quality.

Some of the striking details of this product:

- • High tensile strength

- • Low maintenance

- • Dimensional accuracy

- • High ductility

Aluminum Alloy 2219 Plate

With the aid of our sophisticated infrastructure facility, we are able to cater to the variegated requirements of our clients by offering Aluminum Alloy 2219. Extensively used in the manufacturing of structural components, these products are suitable for high temperature applications as well as high strength weldments. Further, the alloy 2219 offered by us is manufactured in adherence with the industry set standards.

With the aid of our sophisticated infrastructure facility, we are able to cater to the variegated requirements of our clients by offering Aluminum Alloy 2219. Extensively used in the manufacturing of structural components, these products are suitable for high temperature applications as well as high strength weldments. Further, the alloy 2219 offered by us is manufactured in adherence with the industry set standards.Specifications:

- • Gings, Fasteners, Etc.

The following specifications cover Aluminum 2219:

- • AMS 4066

- • AMS 4068

- • ASTM B209

- • ASTM B211

- • ASTM B221

- • ASTM B241 (Pipe- Seamless)

- • ASTM B247 (Forging - Open Die)

- • ASTM B316

- • MIL A-46118

- • MIL A-46808

- • MIL A-8920 (plate)

- • SAE J454

- • UNS A92219

- • QQ A-250

- • QQ A-367 (Forging - Open Die)

- • QQ A-430

Principal design features:

- • AL 2219 is an age-hardenable copper containing alloy of aluminum

Applications:

- • Commonly used in the manufacture of structural components

- • Used in high temperature applications as well as high strength weldments

Machinability:

- • In the annealed condition this alloy is readily machined

Forming:

- • The alloy may be readily formed by conventional methods

Welding:

- • Welding heat input affects the corrosion resistance of this alloy in an adverse manner

Heat treatment:

- • Solution heat treatment is done at 1000 F

- • Followed by a cold water quench (T4 condition)

Forging:

- • Hot forging may be done providing the finished product is given

- • The aging heat treatment to restore corrosion resistance

Hot working:

- • Hot working should be avoided unless it is feasible to give the finished product

- • the aging heat treatment after all hot working is done

Cold working:

- • Cold working by conventional means is readily accomplished

Annealing:

- • Solution annealing is done at 1000 F for adequate time to allow thorough heating, followed by a cold water quench

Hardening:

- • This alloy is hardened (strengthened) by an aging heat treatment

- • By controlled cold working from the solution annealed condition

Other Physical Props:

- • Electrical conductivity 30% that of copper

Physical data:

- • Density (lb/cu. in.): 0.103

- • Specific gravity: 2.84

- • Melting point (Deg F): 950

- • Modulus of elasticity tension: 10.6

Aluminum Alloy 6351 T6 Plates

Keeping in mind the precise demands of clients, we offer a wide range of Aluminum Alloy 6351 T6 Plates (he30). We provide these alloys in various qualities and ranges as per the exact demands of clients. Following the demands of clients, we provide our products in various ranges and other allied specifications. Our products find their wide application in various industries. These can be availed at cost effective rates.

Features:

- • Sturdiness

- • Finest quality

- • High efficiency

Importers & wholesale distributors of aluminium extruded & rolled products in alloy series aa:1050,1060,1070,1080,2014,2024,2011,2017,3003,3004,3005,3105,5052,5754,5083,5086,5056,6061,6082,6351,6020,7075,8011 etc in all tempers of products confirming to astmb209, astmb247, astmb928, ams, en485, en573, en755, din, jis, bs, is standards from mills of eurpean, uk, us origin for defence, marine, railways, aerospace, oil & gas, power & energy, electricals, transport, automobiles, medical, advanced research & opther engineering & industrial applications.

- • Thickness: 0.2mm-200mm

- • Width Range: 100mm-1500mm

- • Other sizes available upon request

- • Surface finish: Bright& smooth surface, without flow lines, slightly oiled to avoid white rusting.

- • Quality of Material: Totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set.

Specifications:

- • Aluminium Alloy 6351 - T6

- • High strength heat-treatable alloy

- • Good corrosion resistance and very good weldability

- • Fast delivery

Perforated Aluminum Sheets

Renowned among the industry leaders, Superfit Engineering Pvt. Ltd proudly engage in manufacturing, supplying and exporting Perforated Aluminum Sheets. To manufacture these Aluminum Sheets we use high quality aluminum that is procured from vendors of high repute after scouring the market. We make these products in the required specifications and at the most competitive rates.

Renowned among the industry leaders, Superfit Engineering Pvt. Ltd proudly engage in manufacturing, supplying and exporting Perforated Aluminum Sheets. To manufacture these Aluminum Sheets we use high quality aluminum that is procured from vendors of high repute after scouring the market. We make these products in the required specifications and at the most competitive rates.Features:

- • Optimum thickness

- • Corrosion resistant

- • Fine finish

Specifications:

- • Holes Type: We can punch following types of holes Round, Square, Oblong, Rectangular, Capsule, Hexagonal, Dimpled, Lipped

- • Size: The maximum Sheet size we can perforated is 2000 mm X 6000 mm

- • Thickness: Maximum Thickness is 10 mm in SS

- • Material: SS, MS, Galvanized Steel, Aluminum, Brass, Monel, Inconel, Titanium, Hastelloy, Duplex, Super Duplex

- • Punching Type: Conventional & CNC Type

- • For Fine Hole Punching: Hole Diameters lies 0.4 mm dia to 2 mm dia

- • Drilling: For Heavy Thickness Sheet: 10 mm to 100 mm

Flat Aluminum Sheets

The Flat Aluminum Sheets offered by us are available in different sizes, grades and thickness options to cater the specific needs of our esteemed customers. These plates find applications in various industries including aviation & aerospace, defense and construction.

The Flat Aluminum Sheets offered by us are available in different sizes, grades and thickness options to cater the specific needs of our esteemed customers. These plates find applications in various industries including aviation & aerospace, defense and construction.Features:

- • Unequivocally plot

- • Engaging look

- • Stunning fruition

Aluminum Alloy Sheet 3003-H14

Aluminum Alloy Sheet 3003-H14 is alloyed with 1.20% manganese, which increases the strength of 3003 over commercially pure aluminum (1100 series). 3003 has excellent workability, weldability, and good corrosion resistance. It is used for drawing, forming, spinning, fuel tanks, sheet metal works and other applications that require moderate strength for an aluminum with good weldability. H14 designates the temper, and means that 3003 has been strain hardened and partially annealed. In this condition, 3003 can be easily formed. Embossing or debossing 3003 in this temper should not strain or crack the aluminum. Â 3003 ALUMINUM TREAD PLATE - Often referred to as diamond plate, it has the same properties of 3003-H14, while excellent at resisting corrosion, and strong for light weight aluminum applications. The diamond trend pattern is slip-resistant and cosmetically appealing.

Aluminum Alloy Sheet 3003-H14 is alloyed with 1.20% manganese, which increases the strength of 3003 over commercially pure aluminum (1100 series). 3003 has excellent workability, weldability, and good corrosion resistance. It is used for drawing, forming, spinning, fuel tanks, sheet metal works and other applications that require moderate strength for an aluminum with good weldability. H14 designates the temper, and means that 3003 has been strain hardened and partially annealed. In this condition, 3003 can be easily formed. Embossing or debossing 3003 in this temper should not strain or crack the aluminum. Â 3003 ALUMINUM TREAD PLATE - Often referred to as diamond plate, it has the same properties of 3003-H14, while excellent at resisting corrosion, and strong for light weight aluminum applications. The diamond trend pattern is slip-resistant and cosmetically appealing.Analysis:

| Manganese (Mn) | Silicon (Si) Max | Copper (Cu) Max | Iron (Fe) | Zinc (Zn) | Aluminum (Al) |

| 1-1.5 | 0.6 | 0.2 | 0.7 | 0.15-0.35 | Remainder |

Mechanical Properties:

| Tensile Strength (PSI) | Yield Strength (PSI) | Elongation in 2" |

| 22,000 | 21,000 | 10 |

Applications:

- • 3003-H14 is widely used for stampings, spun and drawn parts and products, cooking utensils, chemical equipment, builders hardware, storage tanks, truck and trailer components, mail boxes, cabinets, fan blades, awnings, siding, kitchen equipment, decorative trim, architectural uses, signage applications, etc. Where greater strength is required, consider 5052-H32.

- • 3003 Aluminum Tread plate is widely used for truck beds and trailers, walk ways and cat walks, flooring, wall panels, tool boxes, decorative trim, architectural uses, etc.

Machineability and Weldability:

- • 3003-H14 has a machinability rating of 97% when compared to 2011 at 100%

- • 3003-14 can be readily welded using all the common welding techniques.

Heat Treating:

- • 3003-H14 is not heat treatable.

- • 3003-H14 is most widely used of aluminum alloys, pure aluminum with manganese added for strength, approx 20% stronger than the 1000 series alloys. 3003-H14 aluminum sheet has great workability and may be deep drawn, spun, welded or brazed. 3003 aluminum sheet is NON-heat treatable. This aluminum sheet is widely used for general purposes.

- • Aluminium Sheet comes in many different alloys and thicknesses for different types of applications. Aluminium Plate is produced in thicknesses from 3/16" and up and in several different alloys, each with their specific qualities. Choose a thickness to view what alloys we have in stock for that size plate. We stock 3003H14 but we will special order any alloy and any thickness up to 6" thick.

Aluminum Checkered Sheet

Aluminum Checkered Sheet tread plate can be used for a wide range of construction and structural purposes; this is because of its lightweight, durable, low maintenance quality. Its non-slip element allows it to be widely used as vehicle flooring and industry flooring due to its practical and decorative function. 3003-H22 Aluminum tread plate - The brilliant shine of Aluminum tread plate adds sparkle, along with durability. AKA: Aluminum Diamond Plate, Aluminum Tread Plate, Tread Bright, Aluminum Floor Plate, this highly reflective, economical product is widely used in decorative, cosmetic and architectural applications. Having good forming, drilling and welding ability, Aluminum Diamond Plate is easy to fabricate and its raised diamond lug pattern provides good slip resistance. 6061-T6 Aluminum tread plate - Strength, skid resistance, and durability are the primary selling points of this product. Although its mill finish is not as flashy as 3003 grade, 6061 Aluminium tread plate is widely used for industrial applications - flooring, loading ramps, trench covers, dock flooring, stair treads, elevator floors, freezers floors, etc. Offering increased strength and corrosion resistance, 6061 Aluminum Diamond Plate, is easy to weld and machine, but limited formability.

Aluminum Checkered Sheet tread plate can be used for a wide range of construction and structural purposes; this is because of its lightweight, durable, low maintenance quality. Its non-slip element allows it to be widely used as vehicle flooring and industry flooring due to its practical and decorative function. 3003-H22 Aluminum tread plate - The brilliant shine of Aluminum tread plate adds sparkle, along with durability. AKA: Aluminum Diamond Plate, Aluminum Tread Plate, Tread Bright, Aluminum Floor Plate, this highly reflective, economical product is widely used in decorative, cosmetic and architectural applications. Having good forming, drilling and welding ability, Aluminum Diamond Plate is easy to fabricate and its raised diamond lug pattern provides good slip resistance. 6061-T6 Aluminum tread plate - Strength, skid resistance, and durability are the primary selling points of this product. Although its mill finish is not as flashy as 3003 grade, 6061 Aluminium tread plate is widely used for industrial applications - flooring, loading ramps, trench covers, dock flooring, stair treads, elevator floors, freezers floors, etc. Offering increased strength and corrosion resistance, 6061 Aluminum Diamond Plate, is easy to weld and machine, but limited formability.Aluminum tread plate is practical, decorative, durable and economical. Used as decking, stair-tread, walkways and flooring.

- • There are two different Aluminum Tread Plate designs Ali Bright tread plate (also sometimes called Propeller plate) and a 5 Bar pattern (also known as “Vastrap”).

- • We stocks the full range of Ali Bright in alloy 3003 H224 whilst the 5 Bar pattern is alloy 1050. Other alloys and sizing are available on request. Aluminium Bright comes in a sheet size 2438 x 1219mm, whilst the standard size for the 5 bar pattern is 2500 x 1250mm Aluminum Tread Bright thickness is slightly different to Aluminum 5 bar pattern.

Mechanical properties - Tread plates:

| Detailed Description | |||||||||

| Alloy | Temper | Pattern | Thickness | Width | Length | Coil ID | Origin | Payment Terms: | Lead Time |

| 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5052, 5083, 6061 | F, HO, H12, H14, H16, H18, H22, H24, H26, H32, H111, H112, T651 . | finger, 2 bars, 3 bars, 5 bars, propeller and diamond bars. | 0.8 - 6.0mm | 500 ~ 2200mm | under 10000mm or in coil | 300, 400, 500, etc | China | 30% by TT in advance as deposit and 70% balance by TT or L/C at sight; | Within 30 days after receiving deposit |

Packaging & Delivery:

- • Packaging Detail: export standard, covering with brown paper and plastic film then packed with wooden case/pallet

- • Delivery Detail: 30 days after receiving deposit

5086 & 5083 Aluminium Sheet/Plate Price :

- » Aluminium Plate 2014

Rs 600 / Kilogram(s) - » Aluminum Alloy 7075 Plate

Rs 500 / Kilogram(s) - » Aluminium Plate 6082

Rs 190 / Kilogram(s) - » Aluminium Chequered Plates

Rs 190 / Kilogram(s) - » Aluminum Sheet 5052 H32

Rs 250 / Kilogram(s) - » Aluminum Alloy 5083 Plate

Rs 305 / Kilogram(s) - » Aluminium Sheets Alloy 5052

Rs 175 / Kilogram(s) - » Aluminium Patterned Sheets

Rs 220 / Kilogram(s) - » Aluminium Plate

Rs 180 / Kilogram(s) - » Aluminum Plates

Rs 180 / Kilogram(s) - » Aluminium Sheet 3003

Rs 220 / Kilogram(s) - » Aluminium Plate 5083

Rs 210 / Kilogram(s) - » Aluminium Plate 19000

Rs 220 / Kilogram(s) - » Aluminium Sheet 1100

Rs 177 / Kilogram(s) - » Aluminium Plate 5086

Rs 210 / Kilogram(s) - » Aluminium Plate 7075

Rs 210 / Kilogram(s) - » Aluminium Rolled Plates

Rs 185 / Kilogram(s) - » Aluminium Plate 6063

Rs 210 / Kilogram(s) - » Aluminium Sheet 5086

Rs 210 / Kilogram(s) - » Aluminium Plate 5052

Rs 220 / Kilogram(s) - » Aluminium Plate 6063

Rs 210 / Kilogram(s) - » Aluminium Sheet 6061

Rs 210 / Kilogram(s)

Our Sales Associates are available in below Countries :

India, United Arab Emirates, Canada, Angola, Argentina, Austria, Peru, Chile, Spain, France, United Kingdom, Indonesia, Israel, Iran, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Brazil, Colombia, Ghana, Iran, Denmark, Poland, Costa Rica, Egypt, Iraq, Jordan, South Korea, Poland, Azerbaijan, Pakistan, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Saudi Arabia, Bangladesh, United States, Qatar, Russia, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Lebanon, Morocco, Mongolia, Bolivia, Bulgaria, Australia, Afghanistan, Bahrain, Croatia, Venezuela, Ecuador, Netherlands, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya

Our Dealers and Distributors are available in below Cities :

Mumbai, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Chennai, Surat, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Ahmedabad, New Delhi, Bengaluru, Tehran, Calgary, Noida, Riyadh, London, Kuala Lumpur, Rio de Janeiro, Dammam, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Bhopal, Ulsan, Faridabad, Houston, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Melbourne, Madrid, Thane, Navi Mumbai, Pune, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Ludhiana, Moscow, Dallas, Haryana, Colombo, Atyrau, Lagos, Hanoi, Howrah, Sydney, Ahvaz, Mexico City, Doha, Karachi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam